Understanding Road Rollers: Function and Role in Compaction

What Is a Road Roller and How It Works

Road rollers, sometimes called roller compactors, are big machines used on construction sites to pack down materials like dirt, gravel, asphalt, and concrete. These machines have those massive steel wheels that can be either smooth or equipped with vibration systems. When they roll over the ground, they either press down with their own weight or shake things up with vibrations, which gets rid of air spaces between particles and makes everything denser. The vibrating type works especially well on sandy or gravelly soils because the shaking action helps move particles around until they fit together better. Some tests show these vibrating rollers can actually get about 30 percent better results compared to regular non-vibrating ones. This whole compaction process matters a lot when building roads, laying foundations, or putting down pavement since proper compaction keeps everything from shifting later on.

Purpose and Function of Road Rollers in Soil and Asphalt Compaction

Road rollers do two main jobs when it comes to compacting materials - soil and asphalt. When working on soil prep, these machines really pack down the ground beneath roads, filling in those little air pockets that can cause problems later on. This helps prevent things like settling issues and erosion over time. For asphalt work, road rollers press down on the hot mix material until it reaches just the right density. Getting this right makes sure the finished road looks smooth and stays intact longer without developing cracks too soon. Some research from around 2025 suggests good compaction can actually double how long a road lasts before needing repairs, which is quite impressive compared to roads where the compaction wasn't done properly. The way these machines apply pressure and vibrations creates strong base layers underneath that stand up better against both harsh weather conditions and constant vehicle traffic.

Enhancing Subgrade Strength with Proper Compaction Machinery

Getting good results from subgrade work really comes down to picking the right rollers based on what kind of soil we're dealing with and how wet it is. Road failures often start at weak subgrades, which account for around two thirds of all problems. When contractors manage to get compaction levels between 95% and nearly 98% using either vibratory rollers or those old fashioned sheepsfoot types, they cut down on these issues substantially. The equipment makes a big difference in spreading weight evenly across surfaces and stopping those annoying ruts from forming, so roads last longer. And let's not forget the money side of things either properly compacted ground can slash maintenance expenses by almost half. That's why choosing the appropriate roller isn't just some minor detail it's actually critical if we want our roads to stand up over time.

Types of Road Rollers and Their Applications Across Projects

From Static to Vibratory: Types of Roller Compactors

Construction today depends heavily on those special rollers that get the job done right when it comes to compacting surfaces. The static ones usually weigh somewhere between 8 and 12 tons, putting down consistent pressure that works really well with sticky soils like clay. Then there are the vibratory models which mix their weight with fast vibrations ranging from around 1,500 to 3,000 times per minute. These help pack together stuff like gravel much better, boosting how much weight they can handle by about 20 to 30 percent. When working on asphalt roads, contractors often turn to pneumatic rollers equipped with big rubber tires. These machines basically massage the material as they roll over it, squeezing out all those pesky air pockets while keeping the road surface intact and looking good.

| Roller Type | Key Mechanism | Best For | Efficiency Gain |

|---|---|---|---|

| Static | Weight-based compression | Clay, silt, subgrade layers | 15-20% |

| Vibratory | Vibration + weight | Gravel, rocky soils, asphalt base | 25-30% |

| Pneumatic | Kneading (rubber tires) | Asphalt finishing | 18-22% |

Matching Road Roller Types to Different Road Surfaces

Choosing the right roller depends heavily on what kind of materials are being worked with and what the overall project aims to achieve. When dealing with highway base layers, vibratory rollers get the job done about 40 percent quicker compared to their static counterparts for compacting loose aggregate. Smooth drum rollers come into play when laying down asphalt since they help avoid those unsightly deformations that can ruin the surface quality. Getting temperature right matters a lot too. Most professionals will tell anyone who asks that keeping asphalt rollers running above around 120 degrees Celsius leads to better compaction results with less need for multiple passes over the same area. This advice comes straight from industry guides on selecting appropriate road rollers for different situations.

Smooth Wheeled Rollers for Asphalt Paving and Finishing

Smooth wheeled rollers achieve 92–95% density in asphalt through sequential compaction. Their steel drums produce uniform textures, essential for high-traffic roads requiring friction coefficients of 0.4–0.6. Operators typically make 4–6 passes at 3–6 km/h, adjusting speed based on mix temperature to avoid segregation and ensure consistent results.

Vibratory Rollers in Base Layer and Embankment Compaction

High-amplitude vibratory rollers (1.5–2.0 mm) are vital for embankments, reducing soil permeability by 80% in dam projects. They reach 98% Proctor density in railway subgrades within 12–15 passes—compared to over 20 with static rollers. A case study highlights their role in preventing settlement-related failures, which account for 34% of global infrastructure repair costs.

The Science of Soil and Asphalt Compaction with Road Rollers

Road compaction is governed by engineering principles that dictate how machinery interacts with materials. Modern rollers use weight, vibration, and motion to achieve densification crucial for durability and load support. Understanding these mechanics enhances outcomes across construction phases.

Principles of Soil Compaction and Its Impact on Road Integrity

When soil gets compacted, it basically squeezes out all those little air pockets between the particles, making them pack together really tight and create a solid foundation. Some research from last year showed that if the ground underneath roads isn't dense enough, there's about a 40% higher chance of problems with settling down the road. That's why construction crews use those big road rollers to press everything down just right according to what's called Proctor density standards. These standards help figure out the best balance between how wet the soil is and how packed it needs to be. Getting this right stops the ground from settling unevenly, which would otherwise cause annoying cracks and those pesky potholes we all hate driving over.

Achieving Structural Integrity Through Effective Asphalt Compaction

Getting asphalt properly compacted is all about finding the sweet spot between heat levels, when to apply pressure, and how much force to use. If contractors don't pack it enough, those annoying little air bubbles form throughout the road surface which makes everything crack sooner. But go too far with compaction and the aggregates actually start pulling apart from each other instead of sticking together nicely. Research indicates that hitting around 92 to almost 98 percent density in those asphalt layers can make roads last anywhere from seven up to twelve extra years before needing repairs. Most professionals swear by vibratory rollers for this job since they come with settings that let operators tweak the frequency depending on what kind of mix they're working with, something most modern specs now include in their standard compaction procedures.

How Roller Weight, Vibration Frequency, and Amplitude Affect Results

| Factor | Impact on Compaction | Ideal Use Case |

|---|---|---|

| Roller Weight | Determines surface pressure (kPa) | Heavy rollers for deep layers |

| Vibration Frequency | Adjusts cycles per minute (CPM) | High CPM for granular soils |

| Amplitude | Controls drum displacement (mm) | Low amplitude for thin lifts |

Heavier static rollers (10–20 tons) are suited for deep soil layers, while vibratory models operating at 2,500–4,000 vibrations per minute optimize granular material density. Amplitude adjustments help prevent aggregate crushing in asphalt.

Balancing Pressure and Motion: The Mechanics Behind Optimal Compaction

Operators must synchronize roller speed with vibration cycles to avoid under-compacted “shadow zones.” Slower speeds (<4 km/h) allow full wave propagation through asphalt layers. A 2023 field trial demonstrated that combining 2.5 mm amplitude with 30 Hz frequency reduces air voids by 18% compared to static rolling alone.

Improving Road Durability and Long-Term Performance with Proper Compaction

How Effective Compaction Extends Pavement Lifespan

Proper compaction increases pavement density by 7–12%, creating an impermeable surface resistant to water damage and oxidative aging. This prevents the 90% of potholes caused by moisture intrusion (National Asphalt Pavement Association, 2023), allowing roads to withstand over 100,000 equivalent single axle loads before major repairs.

Preventing Cracks, Bumps, and Settlements Through Correct Techniques

Defect-free surfaces depend on maintaining three key parameters:

- Vibration frequency between 25–35 Hz for granular base layers

- Roller speed below 3 mph (4.8 km/h) during final passes

- Asphalt temperature above 212°F (100°C) throughout compaction

These techniques reduce surface irregularities by 60% compared to uncontrolled methods, according to recent construction research.

Case Study: Maximizing Road Life Through Optimal Road Roller Use

A 2023 Midwest highway project used intelligent compaction systems to achieve 98.6% density—3.2% above standard practices. GPS-enabled rollers automatically adjusted vibration patterns across 15 soil transition zones, resulting in a projected 40-year service life with no joint repairs needed in the first five years.

Avoiding the Pitfalls: Risks of Over-Compaction and Under-Compaction

Under-compaction (below 92% density) allows water retention, reducing load-bearing capacity by 37%. Over-compaction (above 102%) damages aggregate interlock. Modern rollers with real-time density monitoring help maintain the 95–98% sweet spot—where pavements exhibit both flexibility and rigidity.

Stages and Best Practices in Pavement Compaction Using Road Rollers

Key Stages of Compaction in Road Construction Projects

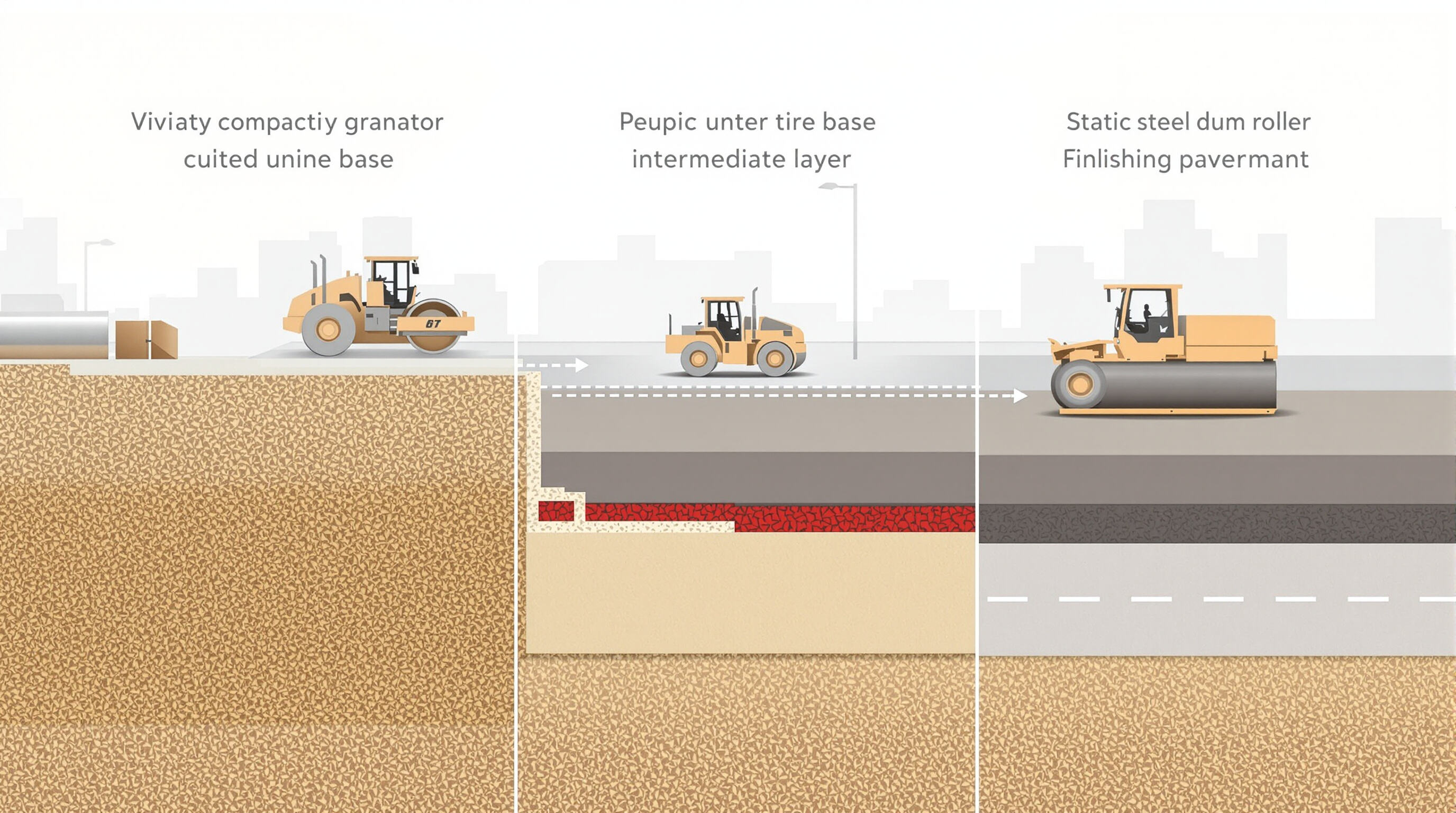

The compaction process typically goes through three main stages: breakdown, intermediate, and what contractors call proof rolling. When starting out, workers usually bring in those big vibratory rollers to pack down the base material, which is often crushed stone or gravel. This first pass gets things going but doesn't do all the work. Next comes the intermediate phase where pneumatic tire rollers roll over the surface multiple times. These machines kind of massage the material as they go, squeezing out air pockets and making everything tighter together. The last step involves static steel drum rollers for what's known as proof rolling. This final pass smooths out any remaining bumps and makes sure weight will be distributed evenly across the road surface. According to that recent report from Road Construction Equipment Analysis in 2023, getting these steps right matters a lot because messing up the order can lead to roads cracking way too soon after they're built.

Roller Application from Base to Surface Layer Compaction

For base layers, high-amplitude vibratory rollers (1.5–2.0 mm) maximize subgrade stability by penetrating deep into granular materials. When compacting asphalt, operators switch to static rollers or lower-frequency vibratory modes (2,000–3,000 VPM) to avoid degrading the mix. Adjusting equipment settings between layers ensures target densities of 95–98% without over-compacting thin surface courses.

Selecting the Right Road Roller Based on Pavement Type and Project Needs

| Factor | Soil/Base Layer | Asphalt Surface |

|---|---|---|

| Roller Type | Sheepsfoot or Vibratory | Static Steel Drum |

| Key Metric | Layer Thickness | Material Temperature |

| Critical Setting | Vibration Amplitude | Drum Pressure (kPa) |

Match roller weight (8–20 tons) and drum width to material depth and project scale—narrow drums exert higher pressure for localized repairs, while wider drums enhance efficiency on large-scale highway projects.

FAQ

What are the main types of road rollers?

Road rollers can be classified into static rollers, vibratory rollers, and pneumatic rollers. Each type serves different functions, depending on the material being compacted and the nature of the project.

How does road roller vibration help in compaction?

Vibratory rollers deploy vibration alongside weight to rearrange soil or aggregate particles more tightly, achieving a higher density compared to static rollers. This is particularly useful for materials like sand and gravel.

Why is compaction important in construction?

Proper compaction helps eliminate air voids, create a solid foundation, prevent settling, and reduce roads' vulnerability to erosion and cracking. This increases the longevity of infrastructural projects.

What are the potential risks of over-compaction?

Over-compaction can damage aggregate interlock in asphalt, reducing the road's ability to handle vehicle loads by affecting its flexibility and rigidity balance.

Table of Contents

- Understanding Road Rollers: Function and Role in Compaction

- Types of Road Rollers and Their Applications Across Projects

- The Science of Soil and Asphalt Compaction with Road Rollers

- Improving Road Durability and Long-Term Performance with Proper Compaction

- Stages and Best Practices in Pavement Compaction Using Road Rollers

- FAQ

EN

EN

AR

AR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE IT

IT NO

NO KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL ID

ID LV

LV SR

SR SK

SK SL

SL VI

VI SQ

SQ ET

ET TH

TH TR

TR AF

AF MS

MS GA

GA HY

HY KA

KA BS

BS LA

LA MN

MN MY

MY KK

KK UZ

UZ KY

KY