Key Specifications

-Engine:Honda GX160

-Power:5.5 HP

-Operating Weight:149 KG

-Exciting Force:30.5 KN

-Compacting Depth:50 CM

Our Service

-On-time Delivery

-Quality Assurance (one year)

-Customized Services (logo,packaging,graphic)

HAND PUSH SMALL COMPACTION MACHINERY

What is the function of a plate compactor?

It is used to compact loose base layers such as soil, sand, gravel, and asphalt. Through the combination of the plate's high-frequency vibration and static pressure, the particles of the material being compacted are made to closely adhere to each other, reducing the porosity and increasing the density. This enhances the bearing capacity and stability of the base layer, preventing problems such as settlement, deformation, and cracking during subsequent construction or use.

FEATURES

Honda GX160 engine, 5.5 horsepower output, 30.5kN vibration force, highly efficient and powerful for compaction.

Single-cylinder air-cooled four-stroke design, excellent heat dissipation, low fuel consumption, suitable for long-term continuous operation.

The operation efficiency is 570 square meters per hour, with a compaction depth of 50 centimeters, achieving a balance between speed and compaction quality.

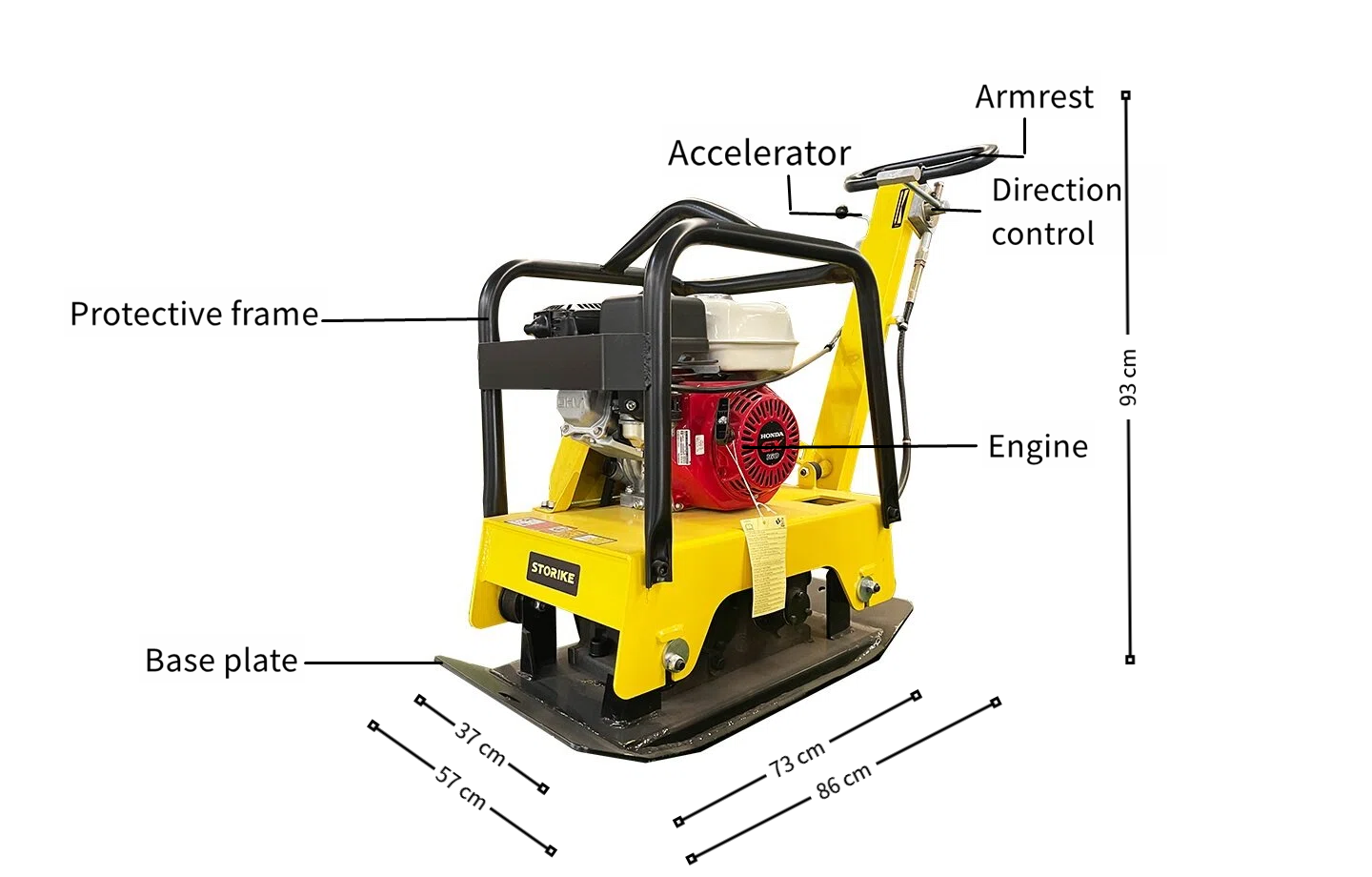

Compact design (86*57*93 cm), suitable for narrow-area operations, and easy to move and transport across various locations.

One-year warranty + 24-hour service. Quick response in after-sales service, no worries about usage.

Product Parameter

| Model | STP160 |

| Engine brand | HONDA |

| Engine model | GX160 |

| Engine type | Single cylinder air-cooled four stroke |

| Number | 1 |

| Power | 5.5 hp |

| Operating weight | 149 kg |

| Excitation frequency | 400 rpm |

| Exciting force | 30.5 kn |

| Compacting depth | 50 cm |

| Travel speed | 25 cm/s |

| Working efficiency | 570 (M^2)/hr |

| Plate size | 73*37 cm |

| Working size | 86*57*93 cm |

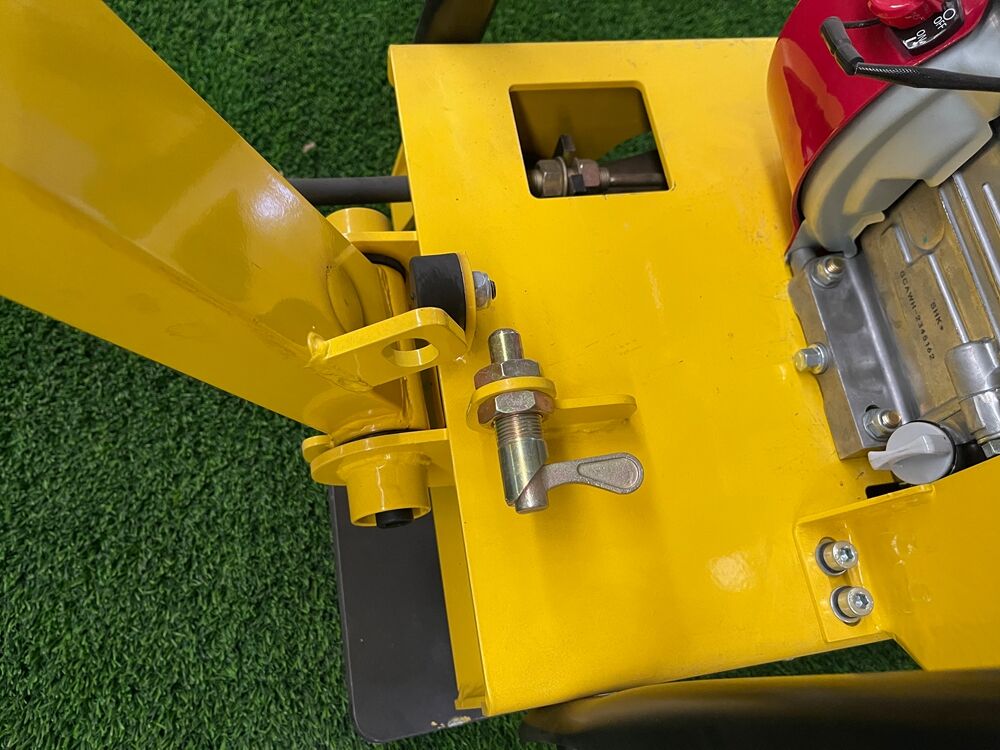

Product details

The STP160 plate compactor not only ensures excellent compaction performance but also has a long service life. It also offers comprehensive after-sales support, safeguarding both the safety and efficiency of the construction process.

1.Power system

Equipped with the HONDA GX160 engine, it is a single-cylinder air-cooled four-stroke model. It has strong and stable power output. The air-cooling design effectively enhances the heat dissipation efficiency, preventing performance decline due to overheating during long-term operation. The four-stroke structure offers advantages such as low fuel consumption, low noise, and more environmentally friendly emissions.

2.Drive & Control System

The STP160 plate compactor maintains a stable traveling speed of 25 centimeters per second. This not only ensures uniform compaction but also allows for flexible adjustment of the operation rhythm, making it suitable for different construction progress requirements.

The equipment's working efficiency reaches 570 square meters per hour, significantly shortening the construction period. It is particularly suitable for large-scale operation scenarios and helps to save labor and time costs for the project

3.Size

The design of the equipment takes into account both operational flexibility and stability. The operating weight is 149 kilograms. The flat plate size is 73*37 centimeters. The spacious working surface can increase the压实 area per unit time and ensure the flatness of the compaction.

The overall working size of the machine is 86*57*93 centimeters. The structure is compact, and it can operate flexibly in narrow spaces, corner areas and other special locations without the need for additional auxiliary equipment.

4.Application

Whether it is sand, clay, crushed stones and other different materials, or large-scale operations and the need for precise compaction, the application of the plate tamper is very extensive:

Road Engineering: Can be used for compaction of the base and surface layers of sidewalks, rural roads, and parking lots, ensuring the smoothness and density of the road surface and effectively preventing post-construction pavement settlement;

Construction: Applicable for compaction operations of house foundations and wall bases, enhancing the bearing capacity of the foundation and ensuring the stability of the building structure;

Landscape, municipal engineering, backfilling after pipeline laying, and leveling and compaction work for small sites.

Preliminary compaction of small building foundations and parking lot bases.

5.Service

Comprehensive service guarantee: Offer a one-year warranty period and a professional service team available 24/7 online. In case of equipment issues, you can call the service hotline at any time. We will respond immediately and provide you with a full range of services including technical consultation, fault diagnosis, and maintenance guidance, ensuring your construction is worry-free.

6.Packing and shipping

We provide wooden case packaging and strictly protect your machine's body as required, including components and paint finish, to ensure no scratches occur. Custom packaging is also available. We will select an appropriate transportation method for you. If you have a freight forwarder, we can also deliver the machine to your designated freight forwarder's location.

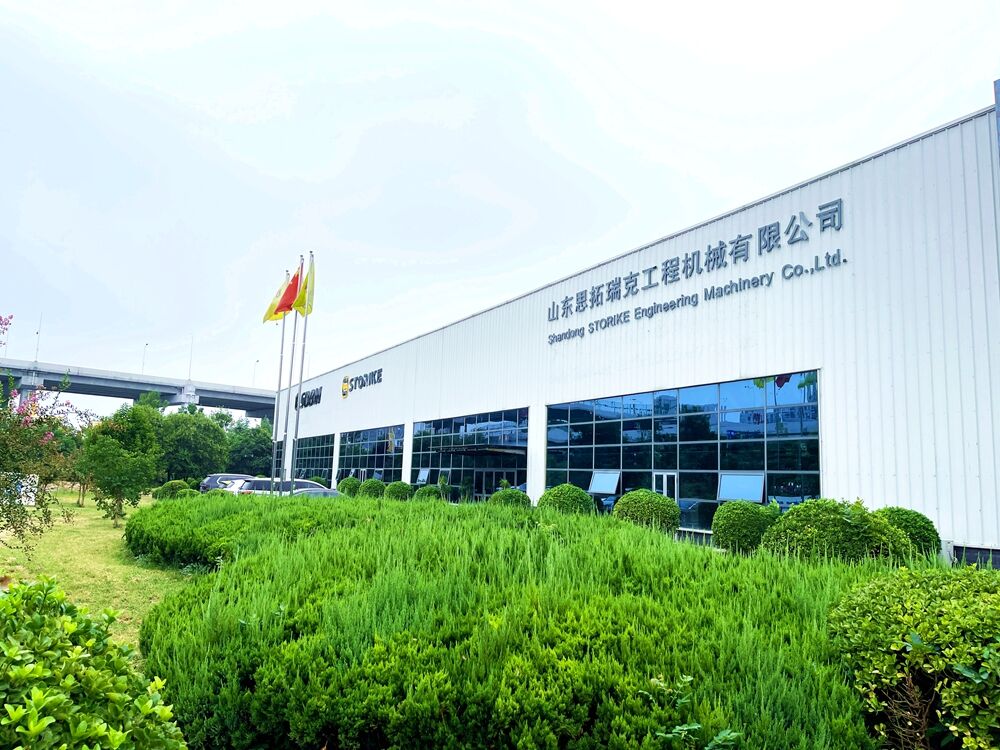

Company Introduction

STORIKE is a professional engineering equipment manufacturer with 15 years of production experience, specializing in products such as light towers, plate compactors, road rollers, excavators and loaders. Our products have obtained CE, EPA and Euro 5 certifications, and can be flexibly customized according to engine types, while providing comprehensive OEM/ODM service support. All products undergo strict quality control. We have participated in the Canton Fair and international construction machinery exhibitions, serving more than 100 countries worldwide. We have 6 dedicated sales and service departments and a 23,000-square-meter modern manufacturing base. We warmly welcome global customers to visit our factory and explore cooperation opportunities.

Number:+86-13963746955

Email:[email protected]

Things to know before buying:

1. Storike is a factory

2. We have sufficient stock and fast production lines

3. Professional sales team to answer your questions

4. Welcome to visit the factory

5. Visualize the entire production process

6. Stable delivery time and privacy protection for shipping

Things to know after purchasing:

1. 365 days warranty and lifetime after-sales service

2. Provide comprehensive user manuals and guidance

3. Provide various auxiliary equipment and accessories

4. No threshold for recruiting agents

5. Lifetime exclusive customer service with 24-hour one-on-one service

Q1: Is the operation noisy?

A1: The four-stroke engine has been structurally optimized, resulting in lower noise levels than ordinary models. This makes the operation more environmentally friendly.

Q2: Can it be used normally when the working surface is narrow?

A2: The tablet measures 73*37 cm. The body is compact and can be used flexibly in corners and narrow areas without the need for additional auxiliary equipment.

Q3: What is the warranty period of the equipment, and where is your factory located?

A3: We provide a one-year whole-machine warranty. Our factory is located in Jining City, Shandong Province, China. If you need, please contact our sales team, who will customize a visit route for you.

Q4: How to get after-sales support in case of equipment failure or remote control problems?

A4: We have a professional service team providing 24/7 reception service. You can call the service hotline at any time. We will respond immediately, offer remote technical consultation and fault diagnosis, and arrange on-site maintenance if necessary.

Copyright © by 2025 Shandong Storike Engineering Machinery Co., Ltd.