Key Specifications

-Engine:Changchai ZN490B | Yanmar 4TNV88 | Kubota V2403

-Power:36 | 34.5 | 33.6 KW

-Operating Weight:4000 KG

-Exciting Force:70 KN

Our Service

-On-time Delivery

-Quality Assurance (one year)

-Customized Services (logo,packaging,graphic)

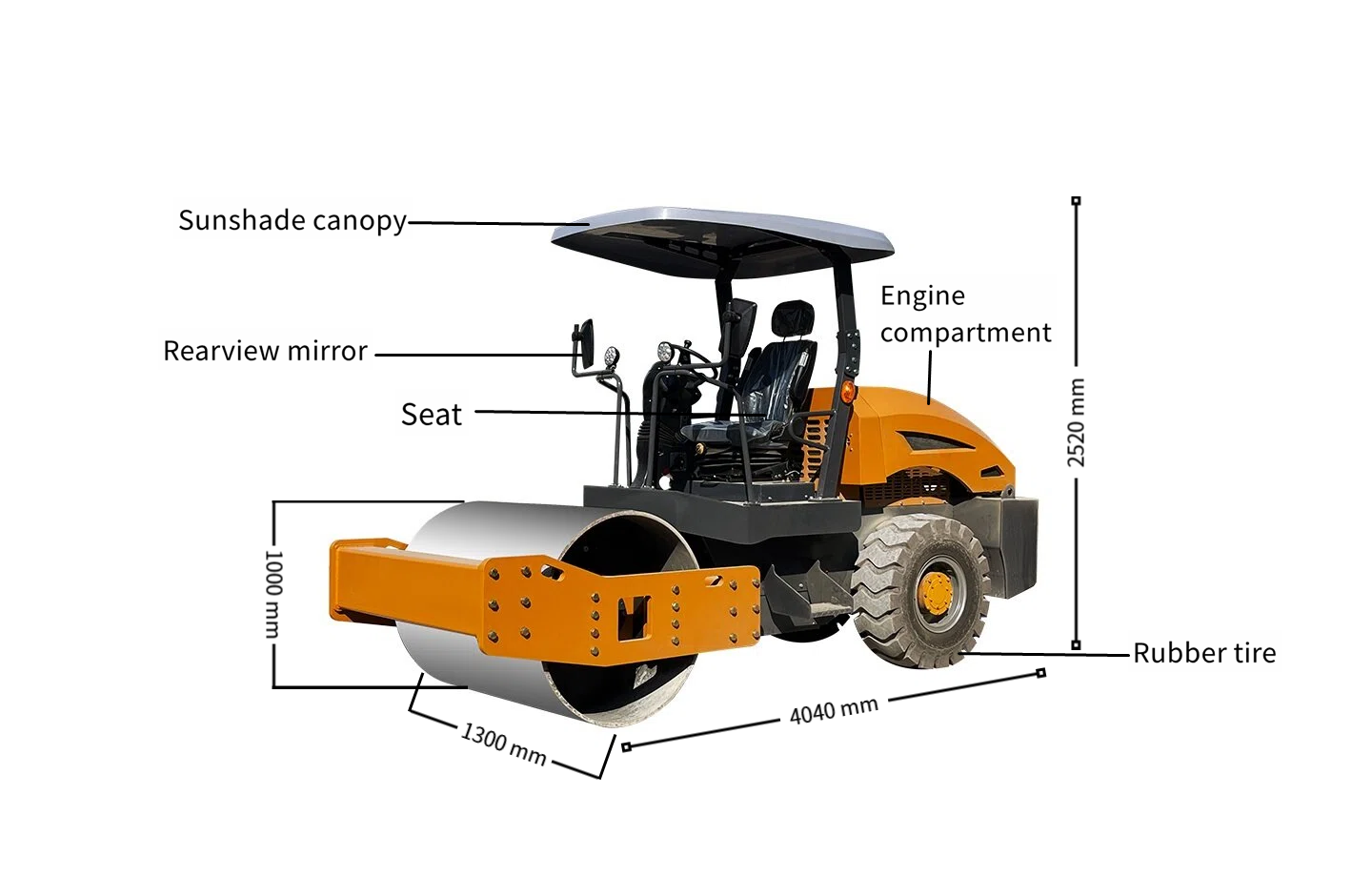

Articulated front steel wheel rear tire roller

What is a remote-controlled road roller?

A remote-controlled road roller is a compaction machine operated via a wireless remote control terminal, eliminating the need for on-board operation. It enables remote control of travel, steering, vibration and other working movements, and is suitable for narrow, high-risk construction sites or areas inaccessible to personnel.

What is the function of a road roller?

The core function of a road roller is to compact road-building materials such as soil, sand, gravel and asphalt mixture through its own weight or vibratory impact force. This improves the compactness, flatness and stability of the compacted materials, reduces their porosity, enhances load-bearing and anti-deformation capacity, and ensures the construction quality and service life of roads, foundations, dykes and other engineering projects.

FEATURES

Product Parameter

| Model | STS04 | |||

| Operating weight | kg | 4000 | ||

| Static line load | n/cm | 125 | ||

| Size | ||||

| Working width | mm | 1430 | ||

| Overall length | mm | 4040 | ||

| Overall height | mm | 2520 | ||

| Turning radius | mm | 5012 | ||

| Drum width | mm | 1300 | ||

| Drum diameter | mm | 1000 | ||

| Wheelbase | mm | 2280 | ||

| Steel drum thickness | mm | 20 | ||

| Tire material | Rubber | |||

| Tire size | mm | 915 | ||

| Tire type | 20.5/70-16 | |||

| Number of tires | 2 | |||

| Supporting method | Support on both sides | |||

| Engine brand | Changchai | Yanmar | Kubota | |

| Engine model | ZN490B | 4TNV88 | V2403 | |

| Engine type | Diesel inline water-cooled four stroke | |||

| Number of cylinders | 4 | |||

| output power | kw | 36 | 34.5 | 33.6 |

| Rotational speed | rpm | 2400 | 3000 | 2400 |

| Electrical equipment | V | 12 | ||

| Drive type | Hydraulic motor driven axle(rear drive) | |||

| Walking characteristics | ||||

| Speed | km/h | 0-7.5 | ||

| Theoretical climbing ability | % | 30 | ||

| Angle | ||||

| Swing angle | 8° | |||

| Rotation direction | ||||

| Steering mode | Hydraulic cylinder steering | |||

| Vibration system | ||||

| Vibrating steel wheel | Front wheel | |||

| Vibration form | Hydraulic power vibration | |||

| Vibration frequency | hz | 54 | ||

| Vibration amplitude | mm | 0.5 | ||

| Excitation force | kn | 70 | ||

| Driver's cab (optional) | ||||

| Cab dimensions | mm | 1450*1450*1700 | ||

| Cab functions | Air conditioning,fan,radio,USB,wiper | |||

| Capacity | ||||

| Lubricating oil | L | 12 | ||

| Hydraulic oil | L | 63 | ||

| Fuel capacity | L | 76 | ||

Product details

The STS04 type road roller is a stable and easy-to-operate medium-sized compaction equipment. With its precise design and reliable configuration, it has become an ideal choice in the field of road construction.

1.Power system

The power system is the core for the efficient operation of the equipment, and the three major brand engines all adopt 4-cylinder diesel inline water-cooled four-stroke models, which can adapt to different working intensities and working conditions:

Changchai ZN490B: With an output power of 36kw and a rotational speed of 2400rpm, it has strong power output;

Yanmar 4TNV88: With a power of 34.5kw and a high rotational speed of 3000rpm, it responds quickly to operations;

Kubota V2403: With a power of 33.6kw and a rotational speed of 2400rpm, it achieves efficient and energy-saving operation.

The electrical system of the equipment adopts 12V power supply, which is stable.

Equipped with a 76L large-capacity fuel tank, a 12L lubricating oil tank and a 63L hydraulic oil tank, it has strong endurance and can meet the requirements for long-term continuous operation, avoiding frequent refueling which may delay the construction progress.

2.Drive & Control System

By adopting the hydraulic motor-driven rear axle (rear-wheel drive) mode, the power transmission is smooth and efficient. The walking speed can be flexibly adjusted within the range of 0 - 7.5 km/h, meeting the speed requirements of different compaction stages.

Equipped with hydraulic cylinder steering, the operation is both lightweight and precise.Combined with a turning radius of 5012mm, it can perform flexible steering even in complex working conditions, significantly enhancing the operational flexibility.

With a theoretical climbing capacity of 30% and a swing angle of 8°, it can easily handle complex terrains such as slopes and uneven ground.

The core vibration system is driven by hydraulic power. The diameter of the front wheel vibration steel wheel is 1000mm and the width is 1300mm. The vibration frequency is 54Hz, the amplitude is 0.5mm, and the excitation force can reach 70kn. It can achieve uniform deep compaction for different materials such as soil, sandstone, and asphalt mixture, and the compaction effect far exceeds the basic standards of the industry.

3.Size

Weight: The operating weight of the equipment is 4000kg. The static line load is 125n/cm. It is equipped with a 20mm thick high-strength steel drum, which has excellent wear and pressure resistance properties, and can effectively improve the compaction quality and the service life of the equipment.

Dimensions: The overall length of the machine is 4040mm, the height is 2520mm, the wheelbase is 2280mm, and the working width is 1430mm. It can achieve wide-range operation coverage.

Optional customization option: An optional cab with dimensions of 1450*1450*1700mm is available. It is equipped with air conditioning, fans, radio, USB interface and wipers, creating a comfortable working environment for the operators, alleviating fatigue from long-term work and improving construction efficiency.

4.Application

The front wheels of the STS04 road roller are equipped with steel rims, which are responsible for efficient compaction and tamping operations. The rear wheels are equipped with dual rubber tires, which ensure the stability of the vehicle's movement and its adaptability to different terrains. Together, they work in harmony to meet the precise compaction requirements for various scenarios. It is widely used in:

· The initial and recompaction operations of asphalt pavement on municipal roads, taking into account both compaction quality and pavement flatness

· Soil and sandstone layer compaction projects for rural roads, county and township roads

· Foundation consolidation treatment in industrial parks, residential areas and parking lots

· Pre-treatment of foundation materials before the laying of squares and sidewalks

5.Service

Comprehensive service guarantee: Offer a one-year warranty period and a professional service team available 24/7 online. In case of equipment issues, you can call the service hotline at any time. We will respond immediately and provide you with a full range of services including technical consultation, fault diagnosis, and maintenance guidance, ensuring your construction is worry-free.

6.Packing and shipping

We provide wooden case packaging and strictly protect your machine's body as required, including components and paint finish, to ensure no scratches occur. Custom packaging is also available. We will select an appropriate transportation method for you. If you have a freight forwarder, we can also deliver the machine to your designated freight forwarder's location.

Company Introduction

STORIKE is a professional engineering equipment manufacturer with 15 years of production experience, specializing in products such as light towers, plate compactors, road rollers, excavators and loaders. Our products have obtained CE, EPA and Euro 5 certifications, and can be flexibly customized according to engine types, while providing comprehensive OEM/ODM service support. All products undergo strict quality control. We have participated in the Canton Fair and international construction machinery exhibitions, serving more than 100 countries worldwide. We have 6 dedicated sales and service departments and a 23,000-square-meter modern manufacturing base. We warmly welcome global customers to visit our factory and explore cooperation opportunities.

Suggested use

Here are some safety tips to help you maintain the machine and extend its service life:

Safety Tips & Maintenance Advice:

· During the operation of the equipment, do not perform cleaning or maintenance work. Rotating parts may cause personal injury.

· It is strictly prohibited to clean parts with gasoline, other fuels or flammable solvents, especially in enclosed areas; the fumes volatilized from fuels and solvents are prone to accumulation, which may cause explosions.

· Regularly check the external buttons of the equipment to ensure their normal functions.

· Provide professional operation and safety training to equipment operators on a regular basis.

· Do not operate the equipment in areas with flammable substances, fuel or flammable vapors.

· After the equipment is out of service, turn off the engine immediately, store it in a clean, dry area out of the reach of children, and ensure standardized storage.

· Do not remove the air filter cover, paper filter element and pre-cleaner while the engine is running.

· Before hoisting, jacking up the equipment or performing maintenance work, be sure to fasten the articulated steering connection in place with a locking rod.

· We provide instruction manuals and operation suggestions. Please use the machine in accordance with the manual to ensure personal safety and avoid machine damage.

Q1: What are the operating weight and core compaction parameters of the STS04 roller?

A1: Operating weight 4000kg, excitation force 70kN, vibration frequency 54Hz, static linear load 125N/cm

Q2: What are the after-sales guarantees for this product?

A2: The whole machine is covered by a one-year warranty. We also offer 24-hour round-the-clock service to promptly respond to inquiries and repair requests.

Q3:How to control fuel consumption costs in daily use?

A3: The core methods for controlling fuel consumption in daily operations: First, choose the appropriate engine model based on the operation materials and compaction requirements; second, avoid prolonged idling and promptly shut down the engine during breaks in the operation; third, regularly maintain the engine (such as cleaning the air filter, checking the spark plugs / fuel injectors), keeping it in the best working condition to reduce fuel consumption.

Q4: What is the warranty period of the equipment, and where is your factory located?

A4: We provide a one-year whole-machine warranty. Our factory is located in Jining City, Shandong Province, China. If you need, please contact our sales team, who will customize a visit route for you.

Q5: How to get after-sales support in case of equipment failure or remote control problems?

A5: We have a professional service team providing 24/7 reception service. You can call the service hotline at any time. We will respond immediately, offer remote technical consultation and fault diagnosis, and arrange on-site maintenance if necessary.

Number:+86-13963746955

Email:[email protected]

Things to know before buying:

1. Storike is a factory

2. We have sufficient stock and fast production lines

3. Professional sales team to answer your questions

4. Welcome to visit the factory

5. Visualize the entire production process

6. Stable delivery time and privacy protection for shipping

Things to know after purchasing:

1. 365 days warranty and lifetime after-sales service

2. Provide comprehensive user manuals and guidance

3. Provide various auxiliary equipment and accessories

4. No threshold for recruiting agents

5. Lifetime exclusive customer service with 24-hour one-on-one service

Copyright © by 2025 Shandong Storike Engineering Machinery Co., Ltd.